COLTRI COMPRESSOR FORCE FOUR Electric

Send inquiryInquiry for: COLTRI COMPRESSOR FORCE FOUR Electric

Force control, in 4 stages

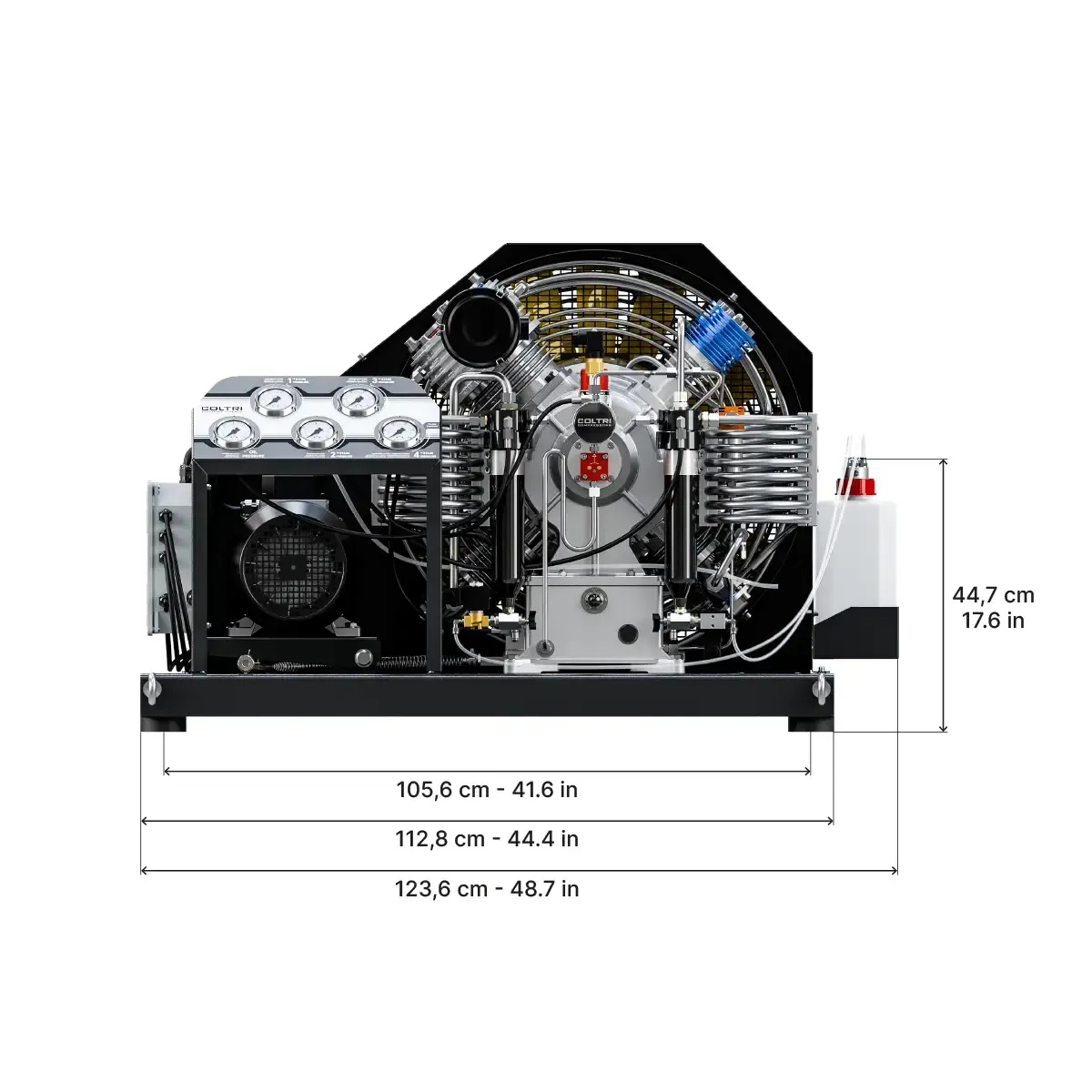

Force Four is the ideal compressor for those seeking power and reliability in even the most intensive uses. With its 4-stage pumping unit, it guarantees high performance and total control at every stage of work.

He goes out of his way to give you the best

The model Force Four meets professional needs that require large charging capacities in hot, poorly ventilated environments or tropical countries. It is equipped with an intuitive control panel and electric motor. The pumping unit, a choice of 3 most powerful, is exposed to ensure a better cooling cycle.

It is equipped with the Hyperfilter stand-alone mounted purification system with automatic condensate drainage. For longer filter life, the Tornado high-pressure dryer is recommended. Available as optional extras: the Presec system for filter saturation control, Megafilter oversized filter cartridges, and 2- or 4-outlet remote refill panel.

Simplicity comes as standard

Imagine having a compressor capable of great performance and endowed with extraordinary robustness. What would all this be without absolute simplicity in operating it? We believe that’s what innovation is for: to make it simpler.

And now for all the details

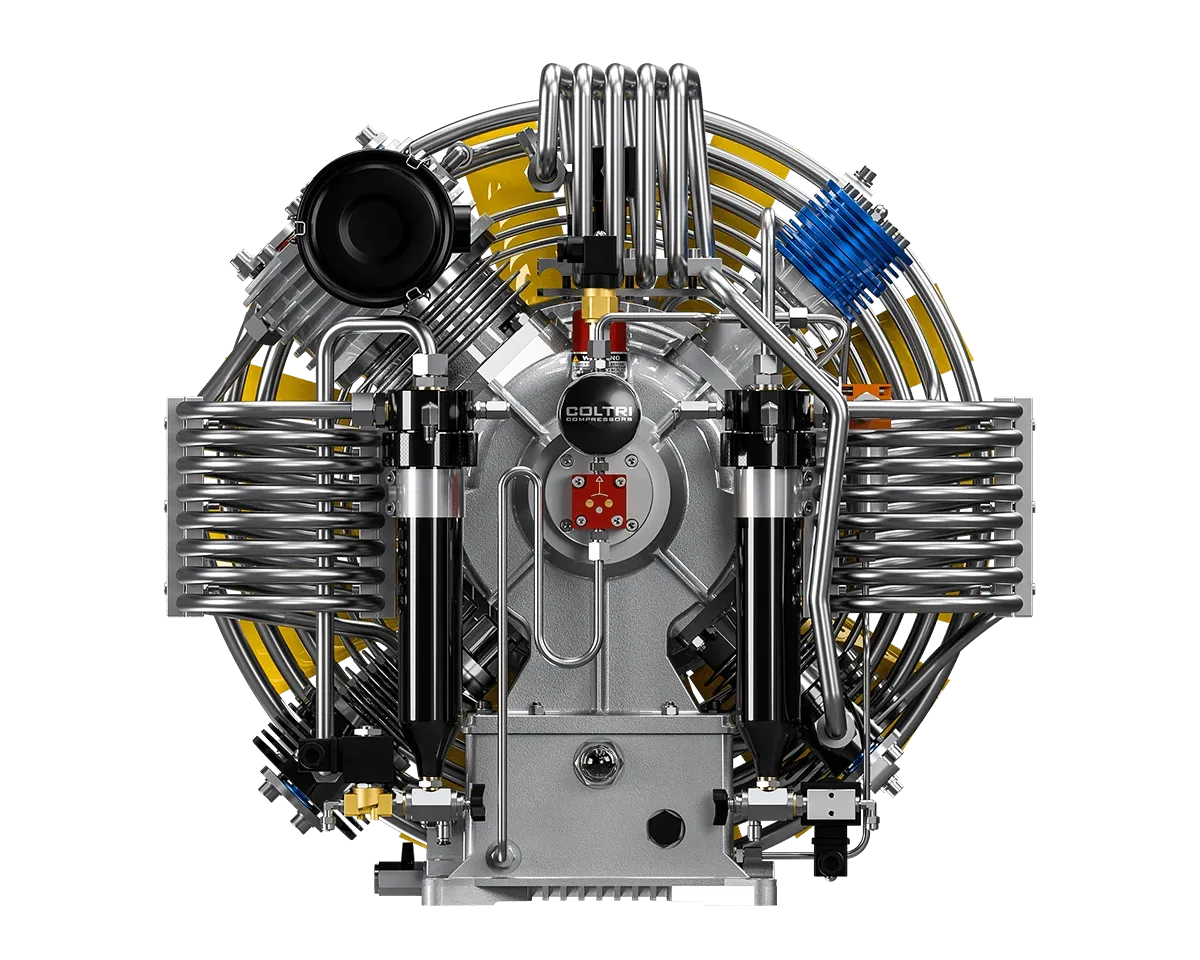

4-stage high pressure pumping unit

- Aluminum monoblock

- Forced lubrication with low-pressure gear pump

- Suction filter: 10 um

- Pipes, fittings and nuts made of AISI 316 stainless steel

- Intermediate condensate separator after the second and third stages

- Minimum lubricating oil pressure switch

- Safety valves after each compression stage

- Special cast iron cylinders with low roughness lapping

- Forged aluminum connecting rods

- Forged steel crankshaft

- High flow valves for the first, second and third stages

- Heavy-duty roller bearings

- Hardened steel third stage with 6 special cast iron bands

- Second and third stages with thrust pads to eliminate lateral forces on the pistons

- Filter system Hyperfilter

Electric motor

One of the key parts of the compressor: the motor transfers motion to the pumping unit through the belt. Single-phase 7.5 kW or three-phase 7.5 to 11 kW electric motor is available on this model.

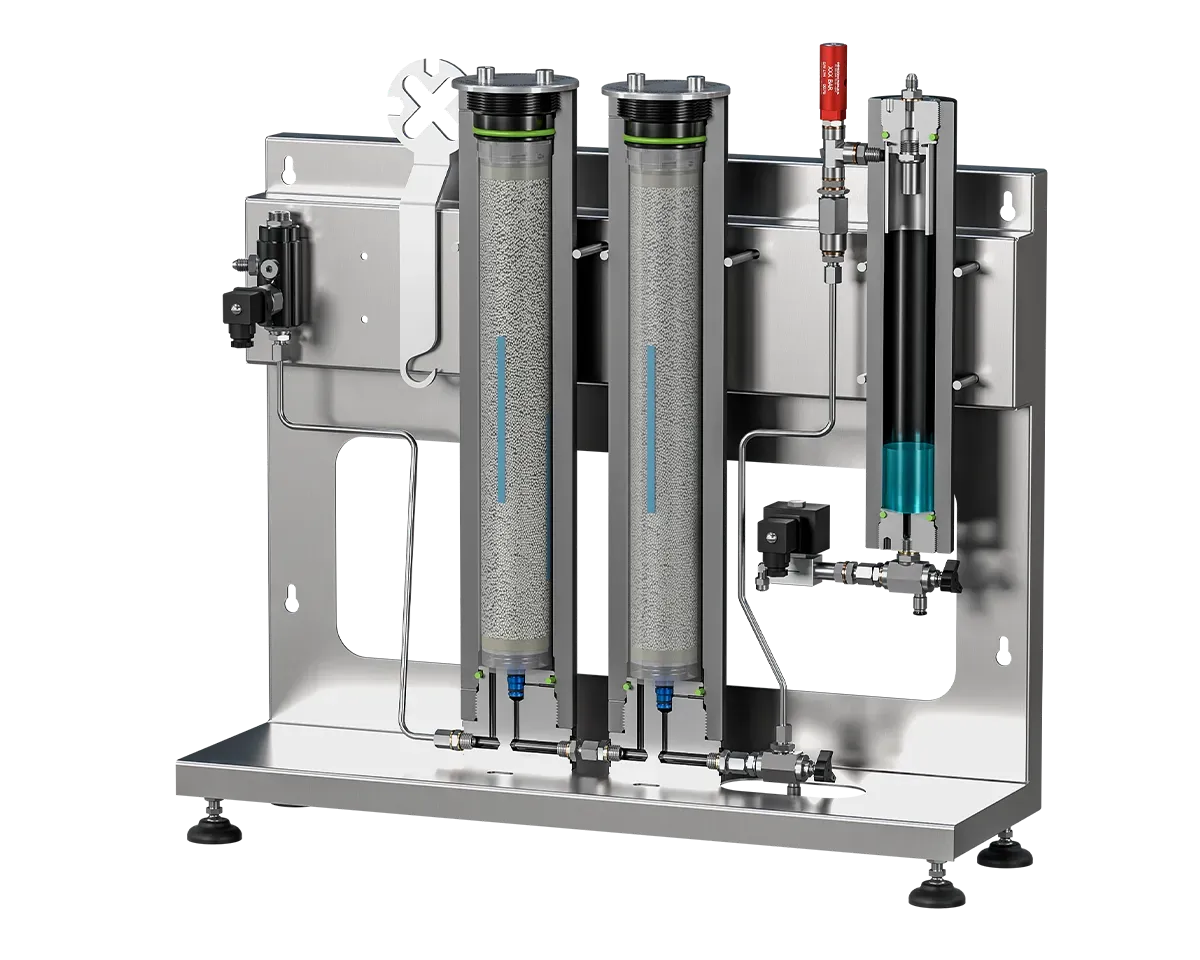

Purification system Hyperfilter

Placed after the last compressor separator and before the pressure maintenance valve, the purification system Hyperfilter enables reliable treatment of the breathing air, according to DIN EN 12021¹ when using original filter cartridges. The separator present between the 2nd and 3rd stages of the purification circuit makes it possible to extract as much moisture as possible. The filtering capacity with inlet air at 20°C and 200 bar is 3,050 m³.

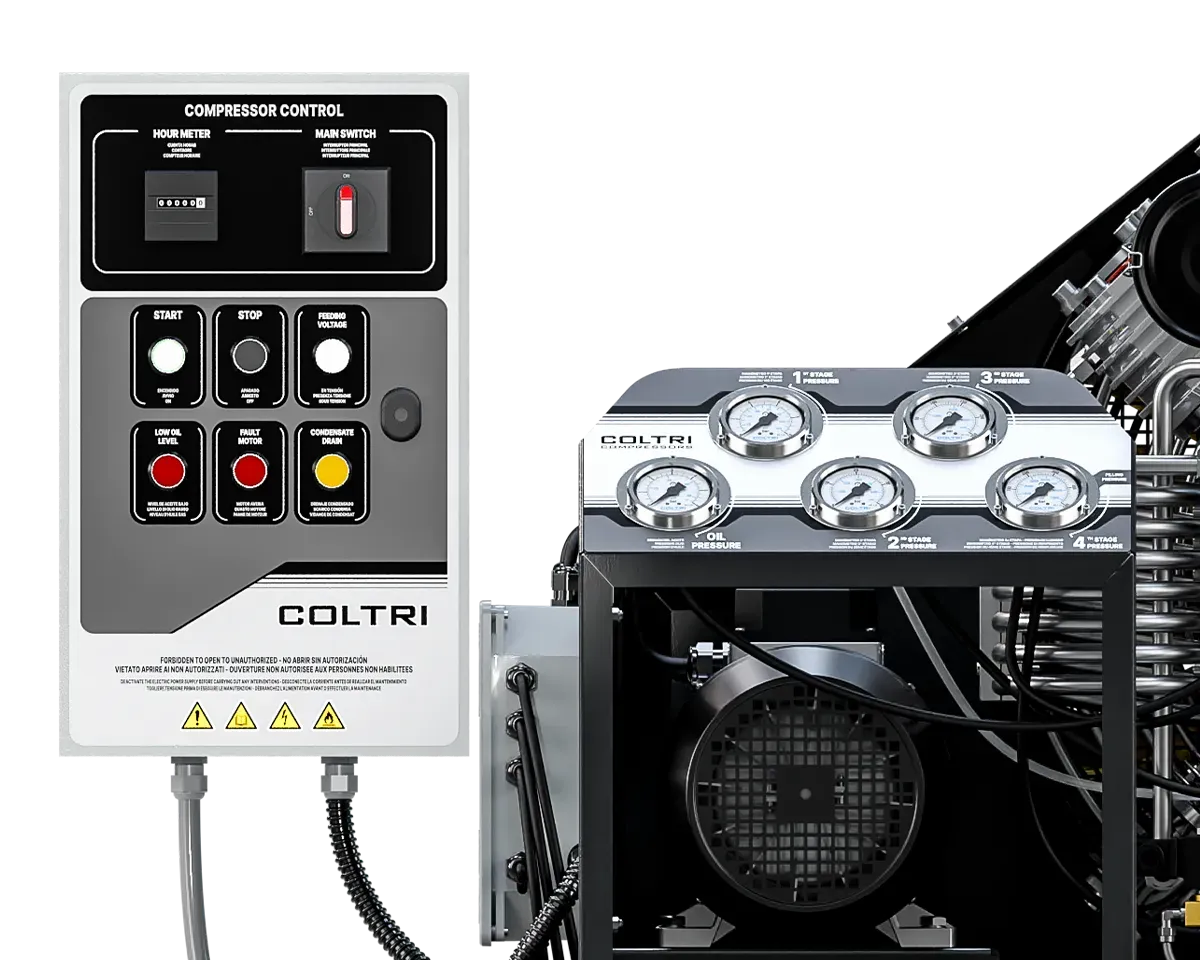

Electrical cabinet

- Motor protection switch.

- Fixed calibration pressure switch 232 or 300 bar.

- Autostart with pressure differential 15 bar. (optional)

- Transformer.

- Drainage of all separators between individual stages and also of the final separator during compressor operation (standard drainage interval every 15 minutes for a period of 6 seconds).

- Timer for automatic condensate drainage device.

- Interstage pressure gauges display the operating pressure for individual compression stages. This pressure information allows the tightness of the valves (inlet and outlet) of each stage to be checked and potential sources of failure to be quickly identified.

Interstage pressure gauges are mounted in the compressor frame.

Frame

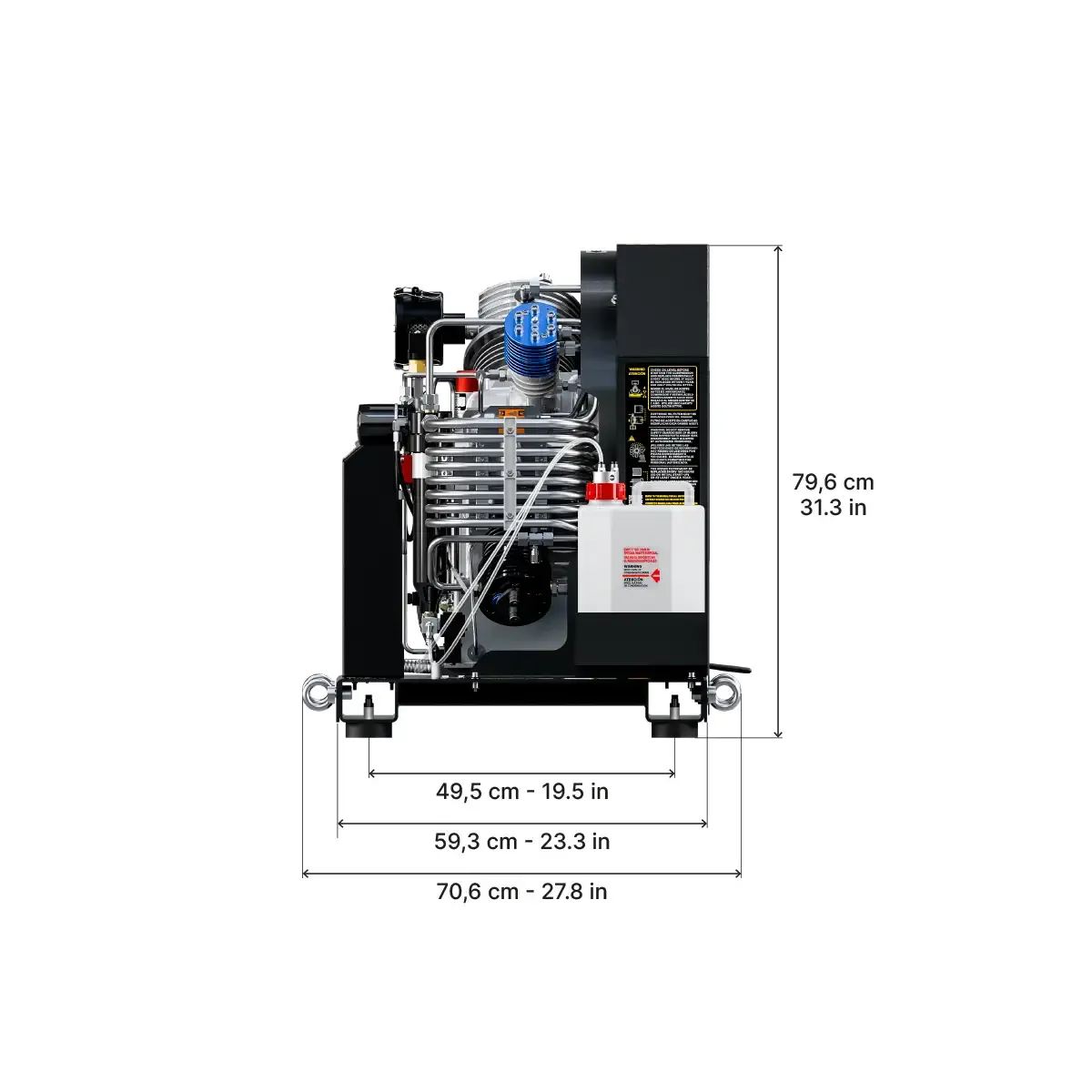

Open frame made for easy maintenance and transportability. Tilting motor carrier plate ensures constant V-belt tension. Protective casing made of thermo-formed material channels cooling air over the cylinders and inter-stage pipes, ensuring high compression efficiency.

Control console equipped with inter-stage pressure gauges, internal temperature indicator, presence and wrong phase sequence alarm, oil shortage alarm, and run stop and manual condensate drain controls allow easy compressor operation and maintenance. Made of steel with scratch-resistant powder coating in RAL 9005 black.

Standard Equipment

4 Cylinder connections from your choice of DIN 232, DIN 300 or INT/YOKE 232 bar4 whips of 1.2 m in lengthPressure holding valveInterstage control manometersDouble filter system Hyperfilter PED certifiedPurification system on “stand-alone” structureAutomatic condensate drainOil level control with automatic shutdownOil pumpFrame color Black RAL 9005

Courier Service

Delivery of ordered products is handled by the courier service GLS.

Delivery Cost

Delivery to locations across EU is from 18 to 42 EUR.

Delivery Time

Delivery time is 3 to 15 working days.

Handling Damaged Packages

If the package is physically damaged, missing contents, or shows signs of being opened, please refuse to accept the shipment.

If you notice damage after receiving the package, inform us as soon as possible via email or phone call.